CNC Metal Punching Services Serving Tucson, AZ Since 1984

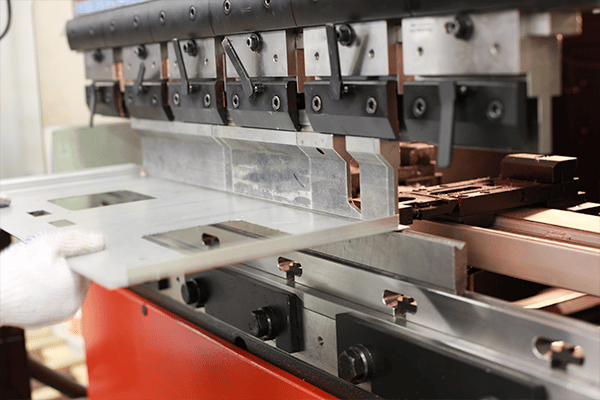

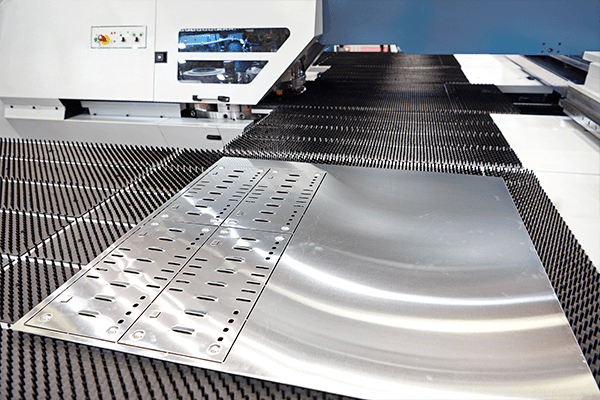

Most punch presses are large machines with either a ‘C’ type frame, or a ‘portal’ (bridge) type frame. The C type has the hydraulic ram at the top foremost part, whereas the portal frame is much akin to a complete circle with the ram being centered within the frame to stop frame deflection or distortion. All punch press machines have a table or bed with brushes or rollers to allow the sheet metal workpiece to traverse with low friction. Brushes are used where scratches on the workpiece must be minimized, as with brushed aluminum or high polished materials.

CNC Punch Press Automation

Computer numerically controlled (CNC) punch presses are able to be run in an automatic mode, according to a pre-built program, to perform the processing of the material. The punch press is characterized by parameters such as:

- Frame type

- Mechanism of delivering power to the ram (mechanical or hydraulic)

- Size of working area (e.g., 2500 x 1250 mm)

- Single or multiple station

- Force rating (for example, 20 tons)

- The type of tool shop and its capacity (e.g., store revolving type, capacity 34 tool)

- Speed or productivity (typically characterized by the speed of strokes with a step movement of 25 and 1 mm)

- Speed of movement without shock (speed-load displacement)

- Maximum weight of workpiece

- Safety features

- Power consumption

- The type of software

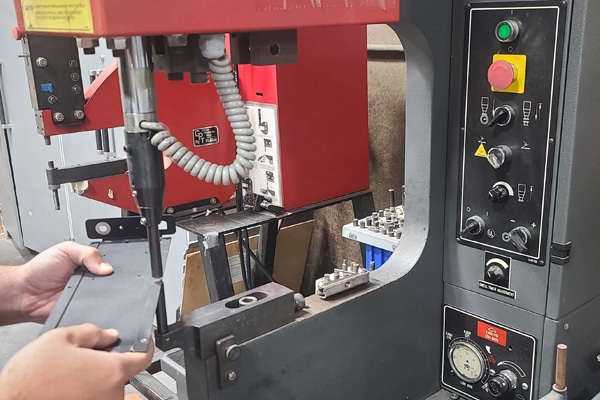

CNC Punch Press Tonnage

Punch presses are usually referred to by their tonnage and table size. In a production environment a 30 ton press is the most prevalent machine used today. The tonnage needed to cut and form the material is well-known, so sizing tooling for a specific job is a fairly straightforward task. According to the requirement, the tonnage may even go up to 2000 to 2500 ton presses.